Custom Is Our Speciality

Experience in any shape or size, large or small, incorporating the latest fastening features

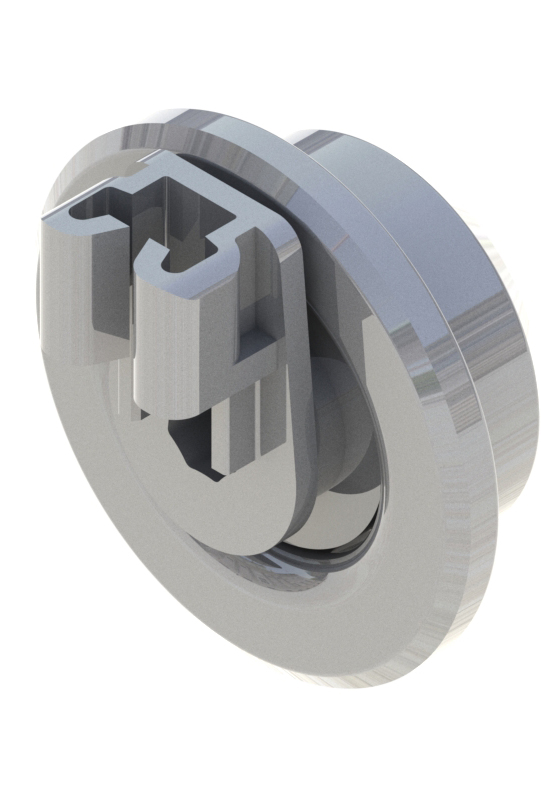

Our expertise is the ability to manufacture radial ball bearings out of Engineering Polymers and 316 stainless. We provide bearing solutions through the use of Design, Innovation and Material selections that best fit the application.

Custom bearings are readily and inexpensively made from plastics. This allows engineers complete freedom to design the bearing around the device rather than attempting to design the device around a limited range of standard bearings. Consider the unconventional by calling KMS Bearings, Inc. We'll work with you to select the right design, size, and material to best fit the application.

See Custom Bearing Showcase for examples of custom made-to-order bearings and their applications. Many of these bearings are available for purchase and can be modified in size, features, or materials.