Bearings by Application

Bearing Solutions for Success

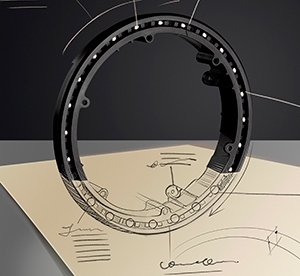

KMS Plastic & 316 Stainless Bearings are used when conventional steel bearings fail to meet your expectations or requirements for success. Our bearings provide an opportunity to solve many of today’s design challenges through the flexibility of polymer & 316 stainless materials combined with fastener technologies.

Below are a few examples of current applications that utilize the features and benefits of a KMS Bearing. If you are looking for a custom bearing for a unique application, please fill out our Application Questionnaire and we will get back to you with a customized bearing solution.

For a more extensive list of applications, please visit Custom Bearing Showcase.