Industrial Applications

ENGINEERING GRADE POLYMER MATERIALS

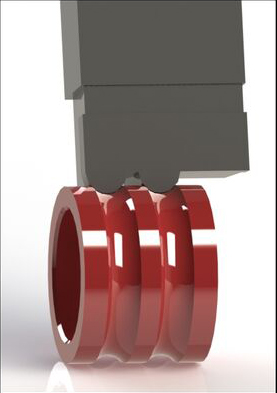

KMS polymer race bearings run in environments without the worry of corrosion or lubrication. KMS polymer materials have low water absorption and offer good wear properties for long life. KMS stainless race ball bearings utilize type 316 stainless which provides superior corrosion resistance when compared to conventional steel and 440 stainless bearings. 316 stainless is more resistant to atmospheric and general corrosive conditions than any of the other standard stainless steel.

TRUE RACE TECHNOLOGY™

KMS produces plastic race radial ball bearings featuring True Race Technology™. KMS employs custom automated speed lathes to the machine in the ball grooves. This removes any molding imperfections and produces a deep ball groove radius that is consistent and concentric for optimum bearing performance and life.

A combination of the right materials and True Race Technology™ bearing design delivers superior performance and life.

Contact KMS today to learn more about how a plastic ball bearing can benefit your industrial application!