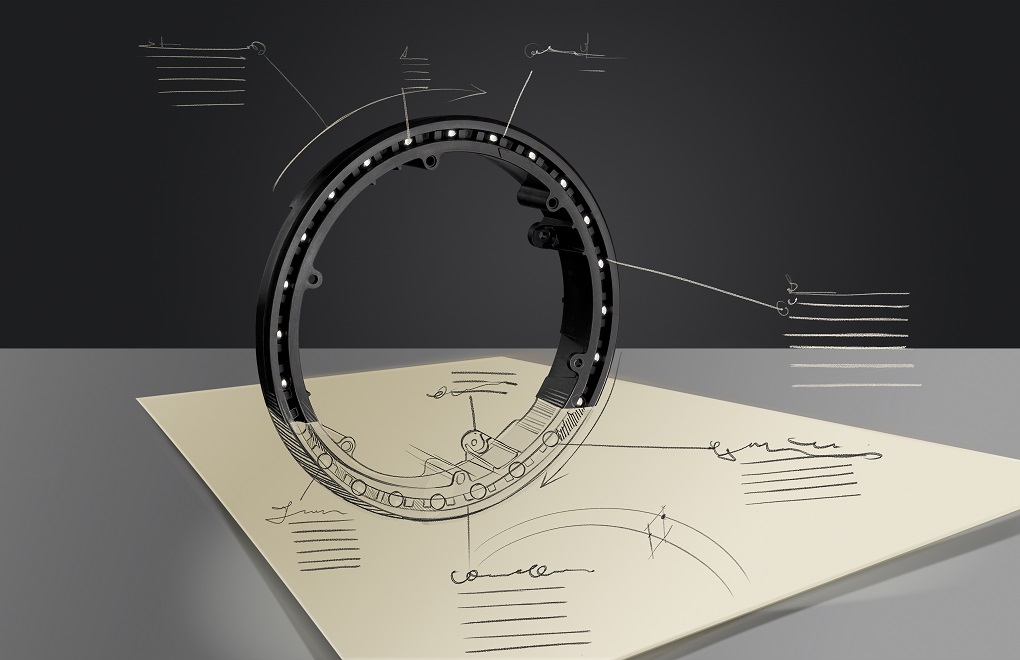

Bearing Prototypes and Samples

Idea to Reality™

KMS wants you to feel confident before you commit to your production needs. We can supply test samples from our stock when available, or complete specials for a nominal lot charge. Our Design and Manufacturing team will take an idea and turn it into a reality. We will work with you by creating a 3D Model utilizing current internal bearing constructions to rapidly respond to your needs.

KMS wants you to feel confident before you commit to your production needs. We can supply test samples from our stock when available, or complete specials for a nominal lot charge. Our Design and Manufacturing team will take an idea and turn it into a reality. We will work with you by creating a 3D Model utilizing current internal bearing constructions to rapidly respond to your needs.

Once a design is created, testing samples can be made from either CNC machining, 3D printing, and/or prototype molding. This blending of technology allows us to make low or high quantity runs of unique designs, sizes, and materials in a short period of time to meet the demands of a fast-paced global marketplace.

Your confidence is our priority. To request prototypes or samples simply fill out our Application Questionnaire and submit or call (714) 970-0280.