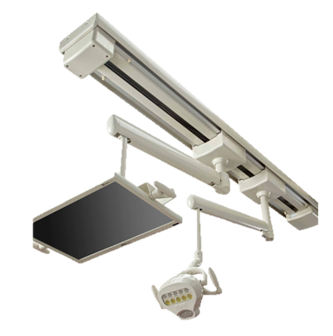

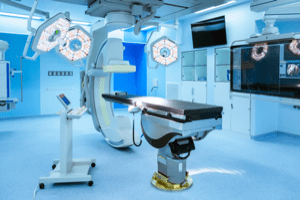

KMS Bearings For Medical Industry

PROVEN MEDICAL PARTNERS

KMS Bearings’ quality system, based on the latest ISO9001 standards, has been developed over 30 years while supplying to the world’s top medical manufacturers. Working collaboratively with our customers, KMS develops strong processes capable of delivering high-quality products to meet customer demands and industry standards.

FOUR DECADES OF EXCELLENCE

KMS’ sole focus over the past four decades has been the development and advancement of plastic & 316 stainless race ball bearing technology. Drawing from this experience, we use a collaborative approach with sales, engineering and the customer resulting in the creation of a design that best fits the application. Our experienced, technically trained personnel understand bearing and engineering principles and use the latest computer design technology and prototype services to deliver superior on time solutions.

KMS TECHNOLOGIES

- Superior Grade Materials: Materials designed for sterilization and the most demanding environments.

- True Race Technology™: Races manufactured for optimum bearing performance.

- Flow-thru Technology™: Designed for cleanliness and sterilization.

- Product Integration: Freedom to design the bearing around the device.

Contact us today to learn more about how a KMS bearing can benefit your medical application!