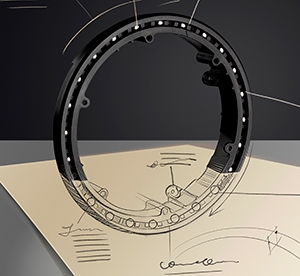

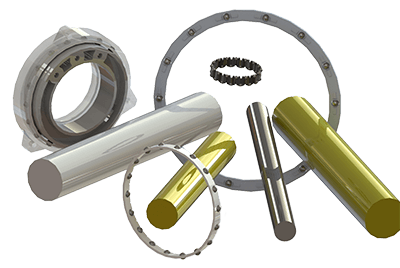

Plastic and 316 SS Custom Bearings

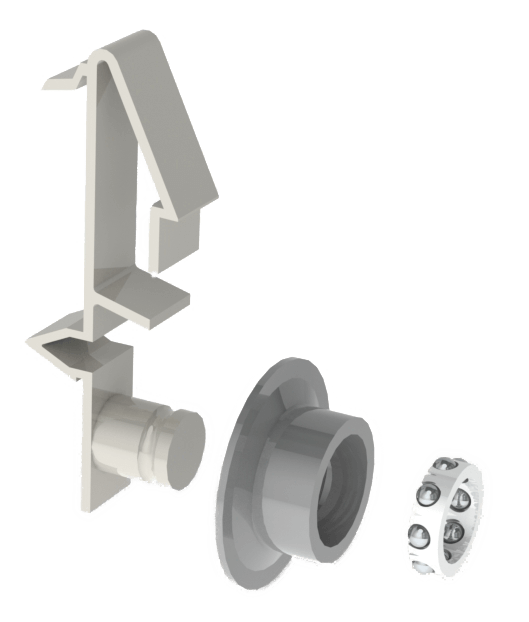

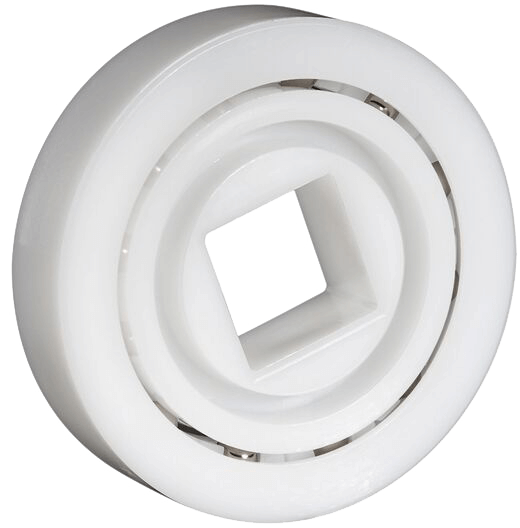

There are numerous modification possibilities for our standard bearing. We can modify the round hole to a hex, square or to a self-mounting fastening design. The standard round outer ring can be modified to a two-hole flange, a sprocket, a gear or a self-mounting fastening system.

Consider the unconventional by calling KMS Bearings, Inc. We'll work with you to select the right design, size, and material to best fit the application.