Thin Section Plastic Ball Bearings

KMS Engineered Polymer Solution For Today’s Design Challenges

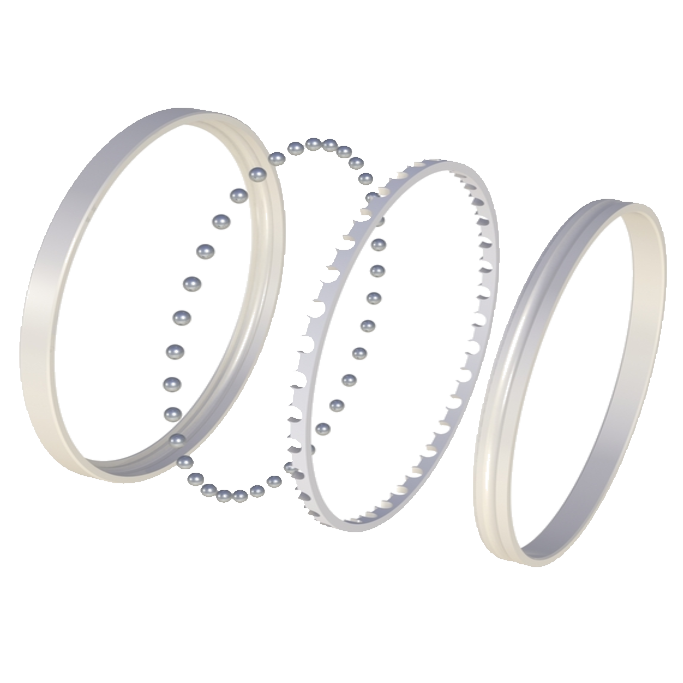

A KMS thin section plastic ball bearing assembly is constructed with POM Acetal engineering polymer for the races & cage and is fitted with SS316 balls. Alternative polymers and balls can be offered when the standard materials are not best suited for the application. The rings are either all machined on a CNC or injection molded with machined ball grooves for greater accuracy, performance and life.

Thin Section Plastic Ball Bearings Options

THIN SECTION PLASTIC BEARING ADVANTAGES:

KMS polymer race thin section ball bearings are less expensive when compared to their steel counterparts. Overall cost reduction can be achieved while providing many solutions to age old problems.

- Cost Savings

- Corrosion Resistant

- Can be Integrated for Value Added Savings (reduction in parts and assembly time)

- Light Weight

- Run in Liquids

- Run Dry – Lube Free

- Can be Nonmetallic - Nonmagnetic

- Lower Start Up Torque

- Clean Room Capable- Sterilizable for Food & Medical Applications

Thin section polymer ball bearings are suitable for demanding applications such as light duty robotics, home satellite TV tracking systems, pan and tilt security cameras, and fueling systems connectors.

When a thin section bearing is required, and your application is light duty with low speed requirements, consider a KMS thin section bearing.

Contact KMS today to find out if a Thin Section Plastic Ball Bearing is the perfect alternative for you!