Roof Top Ventilators

Plastic radial or 4 point contact ball bearing assemblies are used in roof top ventilator applications. They are designed to be maintenance free and operate in challenging environments such as humidity, rain, snow, and hot or cold climates without maintenance.

Plastic radial or 4 point contact ball bearing assemblies are used in roof top ventilator applications. They are designed to be maintenance free and operate in challenging environments such as humidity, rain, snow, and hot or cold climates without maintenance.

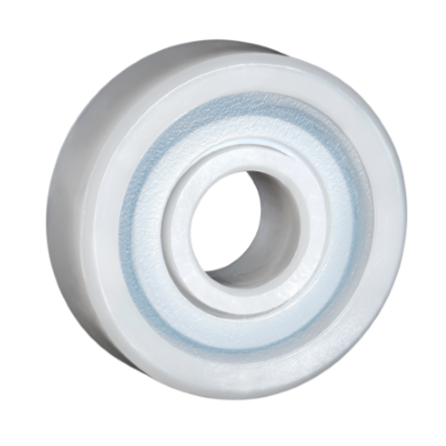

Critical Design features: Acetal POM plastic races fitted with 316 stainless balls. Features a single or double row or 4 point contact TRUE RACE TECHNOLOGY™ ball groove construction for optimum load, stiffness, and moment loading capability.

Critical Design features: Acetal POM plastic races fitted with 316 stainless balls. Features a single or double row or 4 point contact TRUE RACE TECHNOLOGY™ ball groove construction for optimum load, stiffness, and moment loading capability.

Additional reasons for use:

- Dust Shield protection: PTFE seals with Polymer shield backing to reduce dust and dirt contamination. Additionally, a plastic bearing's ability to run without lubrication reduces the chance of attracting contamination to excess grease and entering the bearing.

- Low friction: A KMS plastic race bearing will naturally have a lower coefficient of friction than a metal to metal ball bearing resulting in increased fan rotation at lower wind speeds.

- Weight Savings: A KMS plastic ball bearing is 1/5 the weight of a steel bearing thereby reducing the amount of wind energy needed to rotate the ventilator.

- Value added capability: A KMS plastic bearing can be designed to include mounting features for ease of assembly. A mounting feature can also be integrated with the application to reduce parts count. This capability can reduce assembly time while improving the performance of your product.

Contact KMS today to learn more about how a plastic bearing can benefit your industrial application!