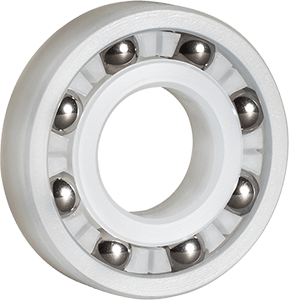

Bearings for Semiconductor Applications

ENGINEERING GRADE POLYMER MATERIALS

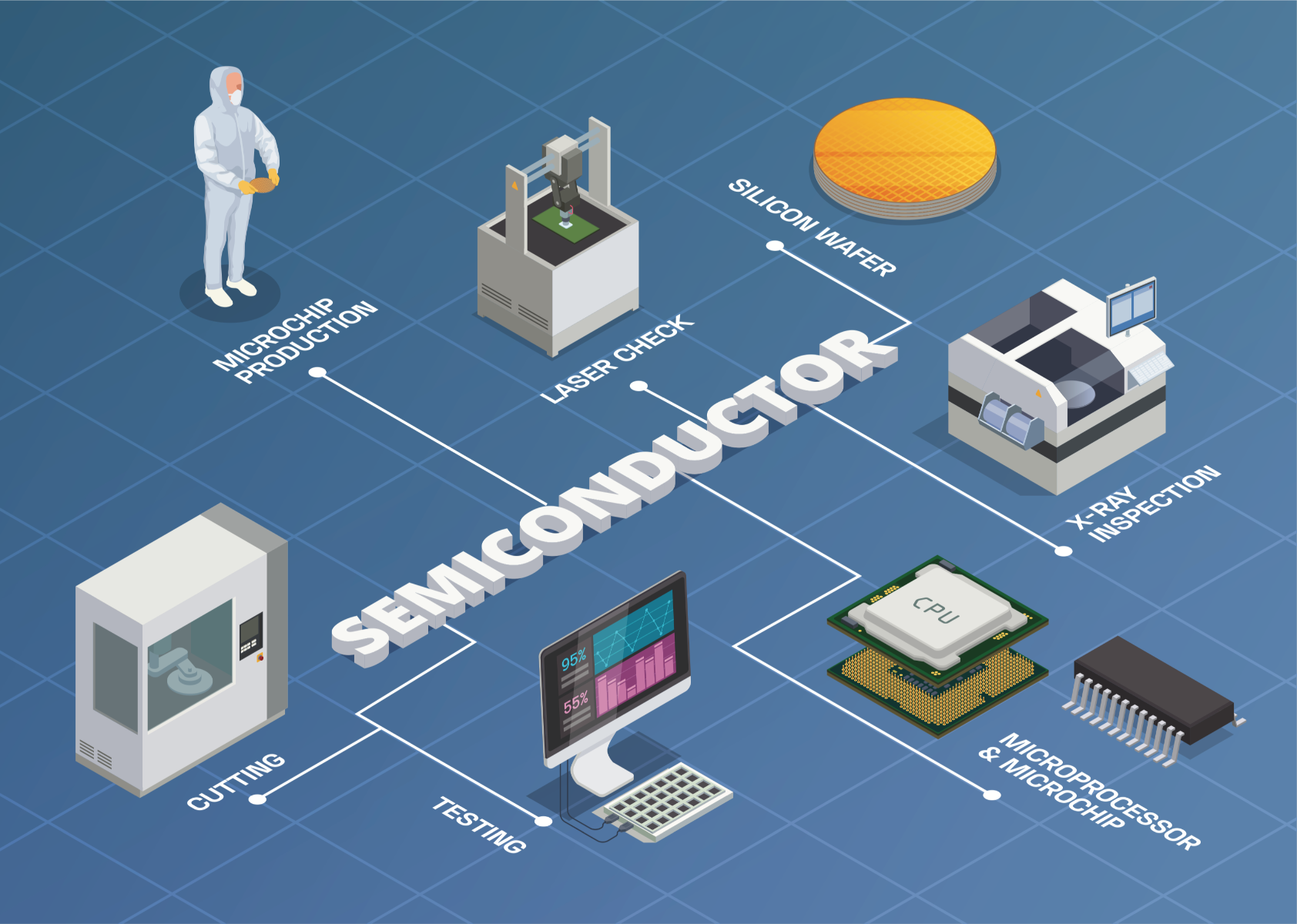

As integrated circuit manufacturers strive to make their chips faster, smaller and less expensive, semiconductor fabrication equipment companies become more dependent on advanced materials and components to achieve the desired performance. Using bearings made from high performance polymers such as PEEK or PVDF rather than standard steels & plastics provides superior chemical and corrosion resistance necessary to survive the semiconductor production processes.

OUR BEARING DESIGNS CAN OFFER SOLUTIONS

The semiconductor manufacturing process is extremely aggressive. Bearings are invariably housed in areas of the processing system where they need to withstand highly corrosive liquids, gases and plasmas often at elevated temperatures or in vacuum conditions. KMS Bearings, Inc., is a leading developer and manufacturer of high performance polymer bearings. Our sales engineers are available to work with you to establish the optimum bearing race materials and design to maximize the performance of your semiconductor manufacturing equipment.

CRITICAL DESIGN FEATURES:

- PVDF or PEEK plastic races and cage

- 316 stainless, Borosilicate glass or SiN2 Ceramic balls

Bearing Construction features a Single and Double row construction True Race Technology™ ball grooves for optimum load, speed and durability. Anti-clogging Flow-Thru Technology™ designs features ensure continued operation while being submerged or exposed to contamination and to tolerate suspended particles in liquids.

ADDITIONAL REASONS FOR USE

ADDITIONAL REASONS FOR USE

- High Heat Capability: KMS bearings made from either PEEK or Kynar® have higher heat capability (180°F to 450°F) over conventional POM plastic or steel bearings.

- Lube-Free: Due to the natural lubricity of engineering polymers combined with the absence of metal to metal contact no lubrication is required. This ability to operate without lubrication allows the bearing to be maintenance free and non-contaminating to the environment.

- Less Friction: Engineered polymer races fitted with either 316 stainless, glass or ceramic balls naturally have less friction than metal to metal steel race bearings.

Contact KMS today to learn more about how a KMS high performance plastic bearing can benefit your semiconductor application! For in stock sizes for both PEEK and PVDF see below for available stock sizes.