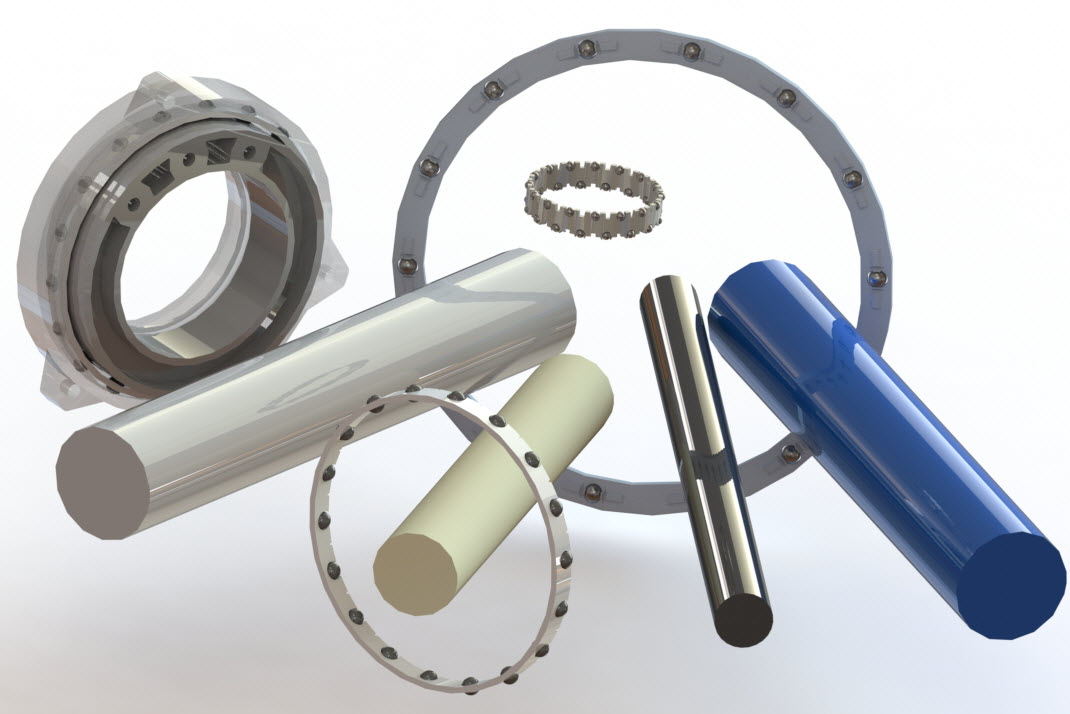

Semi-Custom Bearings

Any KMS existing plastic ball bearing can be easily modified to better fit an application. Unlike traditional bearing manufacturers we offer special sizes and materials in low quantities by modifying standard components or completely machining from extruded rod on our CNC machining centers.

CUSTOM SIZE

Bearings made from plastics have added manufacturing flexibility and can be easily modified in dimension. Our manufacturing processes allow us to either modify a mold tool or use our machining capability to alter a bore size or an outside diameter or width. If the required size cannot be achieved by modifying a standard size, our CNC turning centers give us the ability to manufacture the bearing completely from scratch without mold tooling charges into a modified standard bearing. Once high quantities are reached our team can discuss alternative production methods to improve efficiencies and further reduce cost.

CUSTOM MATERIALS

A Standard KMS Plastic ball bearing features Acetal (POM) for races and ball retainer. Acetal is a superior general purpose engineering polymer that provides an excellent balance of desirable properties that bridge the gap between metals and ordinary plastics. When the standard material is not the right fit we have a host of approved materials that may be a solution for you. These alternatives are available in rod form thereby making them available in low quantities without a mold tooling investment.

The alternative materials are:

- PEEK® - For high temperature –up to 450°F

- Polypropylene - For increased chemical compatibility in lower performance environments

- Valox® PBT Polyester - For increased chemical compatibility while maintaining POM level of performance. Can be Gamma sterilized.

- Kynar® PVDF - For specific increased chemical compatibility while exceeding POM level of performance. Can be Gamma sterilized

- UHMW-PE- For applications that require superior abrasive resistance capability