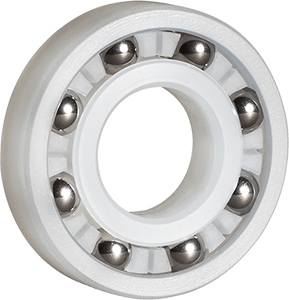

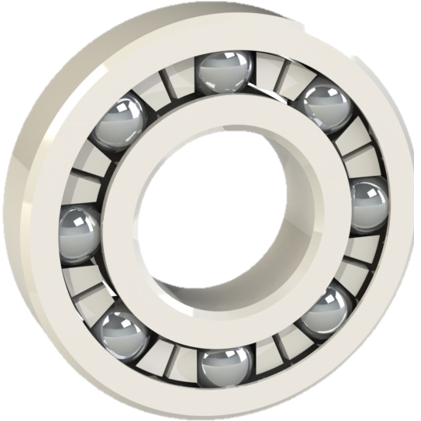

Plastic Radial Ball Bearings

Plastic bearings are not all created equal - The difference is in the Manufacturing Methods, Construction and Design

KMS Bearings is a plastic radial ball bearings manufacturer utilizing engineering polymers such as Acetal POM, PEEK, PVDF, and PBT. Bearings manufactured with these materials are suitable for a wide range of applications including Food, Medical, Pool and Spa, Marine, Semi-Conductor, Business Equipment and Automotive to name a few.

Bearings produced with these materials can run in and around liquids or can run dry without the worry of lubrication.

KMS has the following materials available for specific uses:

- POM (Celcon® Acetal) : Standard material for general purpose

- PEEK: Extreme performance, high temperature, and sterilizable

- PVDF (Kynar®, Solef®) Extreme chemical compatibility and mechanical performance, and sterilizable.

- PBT (Valox®) Chemical resistance, autoclavable, and gamma sterilizable. General mechanical performance

BEARING CONSTRUCTION- The KMS Difference

A KMS standard plastic ball bearing has polymer rings and cages fitted with either 316 stainless or borosilicate glass balls. KMS bearings feature True Race Technology ™ construction; a precision machined deep ball groove race that does not compromise the depth or the design of the ball groove. The result is longer life through lower friction from a more precise radius groove profile. For additional information on machined vs. molded raceways please contact KMS engineering.

For underwater applications, a KMS plastic bearing features a Flow-Thru Technology™ design that allows suspended particles to enter the bearing and flow through without clogging and locking up. This is achieved by the very nature of the rings and cage being made of plastic, the design and clearance of the cage, and race groove geometry. This proven technology was developed through its use in the Pool and Spa industry for over 30 years.

PLASTIC BALL BEARINGS MATERIALS

- RINGS: POM (Celcon® Acetal), PEEK, PVDF (Kynar®, Solef®) PBT (Valox®). For additional information on these materials click here.

- BALLS: Standard balls are 316 stainless. When necessary, other types of balls are available on a special order basis. Click here for additional information

- BALL RETAINER (CAGE): Standard ball retainers are Polypropylene or Acetal in natural or black color. When a higher load or increased flow-through capability is required, the bearing can be made without a cage for a full complement design.

- SHIELDS/SEALS: Open design is standard. In some sizes, we can provide either polymer shields or PTFE seals on a custom made-to-order basis. A minimum order will apply for a custom production run.

- TEMPERATURE FOR STANDARD MATERIALS:

-

- Acetal POM Cage: -40°F to 180°F

- Polypropylene Cage: -40°F to 140°F

- PEEK Cage: -20°F to 338°F

- PVDF Cage –25°F to 183°

- PBT (Polyester): -40°F to 158°F

FEATURES & BENEFITS

- SUPERIOR CORROSION RESISTANCE: Most bearing failures today are caused by corrosion. KMS plastic bearings can be utilized in environments destructive to conventional bearings.

- CAN BE WASHED DOWN: They can be washed down without having to re-lube for rust prevention.

- RUN IN LIQUIDS: Sea water, detergents, solvents, gasoline and hostile chemicals are no problem!

- MADE FROM FOOD + MEDICAL GRADE MATERIALS

- CAN RUN DRY IN SLOWER SPEEDS: Polymer bearings do not require oil or grease for corrosion protection or to reduce friction

- NON MAGNETIC BEARINGS: Polymer race bearings when fitted with either glass, ceramic or polymer balls become a non-magnetic option for MRI X-ray applications.

- HYGIENIC: Plastic race bearings can be washed down, will not rust, do not require any lubrication, and can be sterilized unlike a metal bearing that rusts, requires lubrication, and cannot be fully sterilized .

- HIGH HEAT CAPABILITY: A KMS plastic bearing made from a high temperature polymer can run at higher temperatures up to 383 °F.

Reference: 1. Boyer, Howard E., and Timothy L. Gail, eds. Metals Handbook Desk Edition. Ohio: American Society for Metals. 1985