Custom Built For You

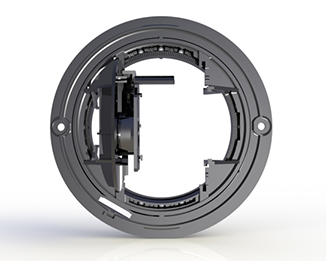

Thin Section Plastic Ball Bearing

A KMS thin section plastic ball bearing can be custom built for you either by modifying an existing standard bearing or creating a unique design to best suit your application.

Our expertise is the ability to manufacture thin section ball bearings out of engineering polymers. We provide bearing solutions through the use of design, innovation and material selections that best fit the application. This allows engineers the complete freedom to design the bearing around the device rather than designing the device around a standard bearing.

WHAT GOES INTO MAKING A CUSTOM BUILT BEARING?

APPLICATION REVIEW

The application review form begins the process of assessing the needs or requirements for the application. Filling out this questionnaire in its entirety will help KMS determine the right material and design features.

COLLABORATIVE APPROACH

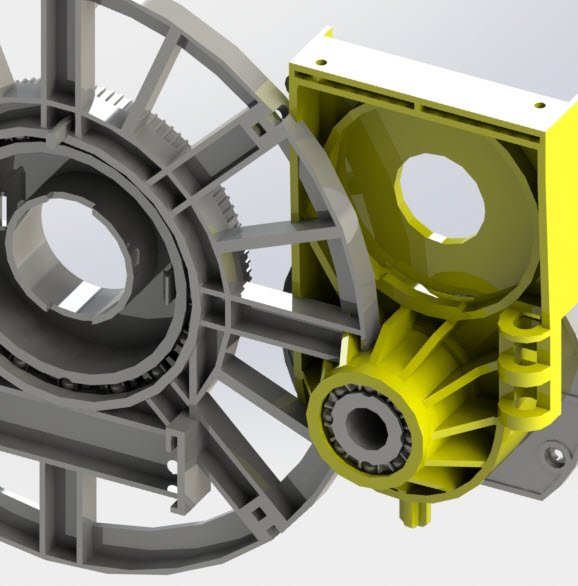

We use a collaborative approach with sales, engineering and the customer to create a design that achieves your objectives. Our experienced technically trained personnel understand bearing and engineering principles and use the latest computer design technology and prototype services to deliver superior on-time solutions.

CONCEPT TO MODEL TO MANUFACTURING

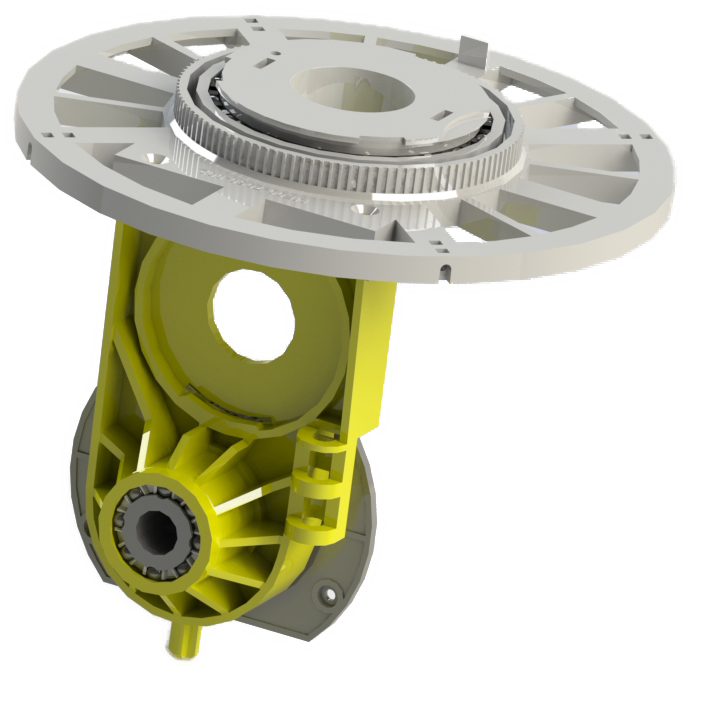

IDEA TO REALITY™

KMS Design and Manufacturing Technology will take an idea and turn it into a reality. We will work with you by creating a 3D Model utilizing current internal bearing constructions to rapidly respond to customer needs. Once a design is created, testing samples can be made from either CNC machining, 3D printing and/or prototype molding. This blending of technology allows us to make low or high quantity runs of unique designs, sizes, and materials in a short period of time to meet the demands of a fast-paced global marketplace.

WHERE ARE KMS CUSTOM BEARINGS USED?

Click Applications for examples of custom-designed bearings by industry.